Congratulations on 30 Years of Service Joe!

Happy Retirement LeeAnn!

Congratulations to Jeremy Campion for 30 Years!!

BTM Purchases 2 New 500's

BTM Purchases Two New Vertical Turning Centers

BTM Purchases and Installs New Mazak 6800

Bill Bowman to Receive Lifetime Achievement Award

BOWMAN PURCHASES NEW MAZAK 6800

HAPPY FOURTH OF JULY

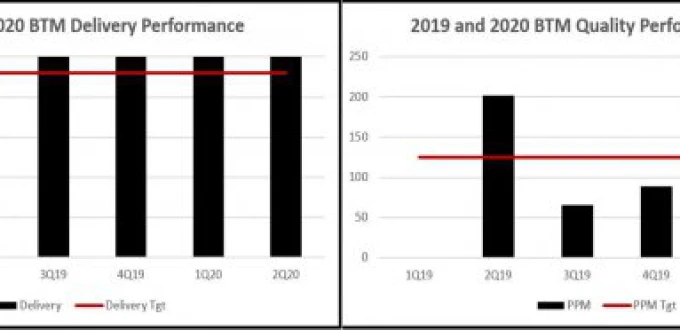

BTM Quality & Delivery Performance 2nd Qtr 2020

New Capability - Shapers

Happy Birthday Bill

Unparalleled Precision Machining

BTM Awarded Partner by John Deere

BTM Achieves 56 PPM for last 12 months

The 3 C's That Make or Break Precision Machining Companies

Bowman Tool & Machining, Inc Delivery Performance

BTM Quality Highlights

Bowman Tool Celebrates Zero Defects for August

Manufacturing Perfection with CNC Machining

Use of Planetary Pinion Carriers and Their Production Benefits with Precision Machining